Menu ☰

Fastener Pull Out Strength in Metal to Wood

What it is and why it matters. Pull out strength is the amount of pounds it takes to pull a fastener out of a given substrate using upward force. There are many different factors that can effect pull out strength, but the main factors are the diameter of the fastener, the diameter of the threads, and the density of the substrate. Let’s look at each of these and why pull out strength is important.

Fastener/Thread Diameter and Thread Length

The most important factor in a fasteners pull out strength is the diameter of the fastener and threads. The reason for this is that the smaller the diameter than less material needs to be displaced in order to pull the fastener out by upwards force. The larger the fasteners diameter, then more of the substrate material needs to be displaced to pull out the fastener, which means more upwards force is going to be required.

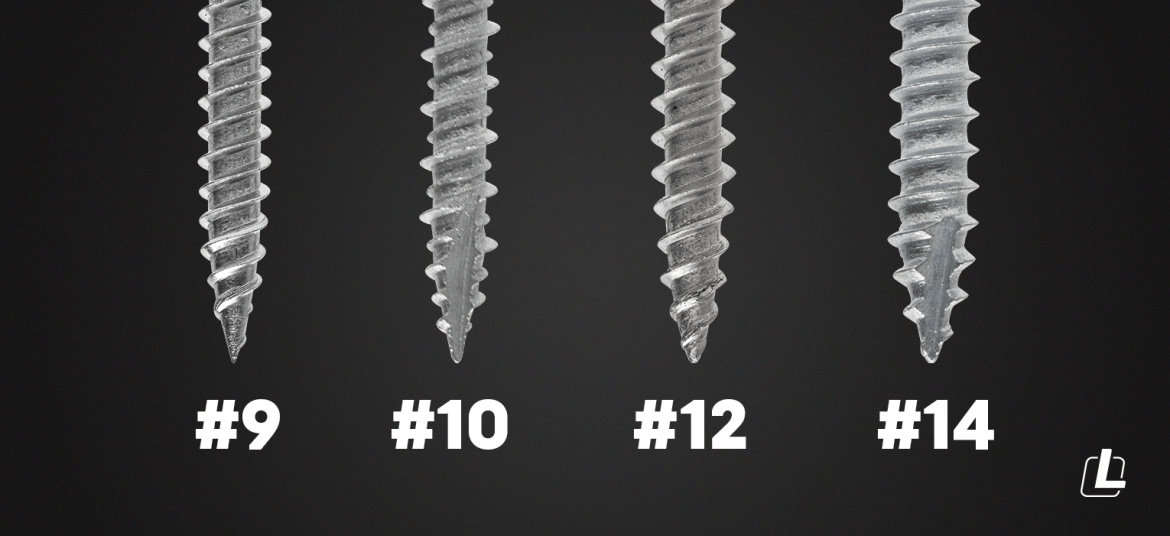

The most common diameter is #10, but if greater pullout strength is needed there are also #12 and #14 fastener diameters. In addition to fastener diameter there are differences in thread types. For example, some fasteners utilize a deep thread, adding more surface area to the threads which increases the depth that the threads cut into the substrate. This means a #12 with deep threads should have a higher pull out strength than a regular #12.

Substrates and Pull Out Strength

Understanding the features that increase the pull out strength of a fastener is important, but it all depends on the strength of the substrate. When drilling into wood, there are a couple of factors that will indicate how well a fastener will hold.

Lumber

When it comes to pull out strength in lumber, the species of wood is what matters most. Different types of wood will have different density. To get an idea of a specific woods density you can look-up what is called the “specific gravity.” The specific gravity of a wood is the density of the wood as a ratio of the density of water. The density of water is 1,000kg, and so if the density of a given wood is 500kg then that wood’s specific gravity is 0.5. The higher the specific gravity then the more dense the wood, and the greater the pull out strength will be.

Engineered Woods

When it comes to engineered woods such as plywood and OSB, the density does not help as much in determining whether the substrate will have a higher or lower pull out strength. The reason for this is that plywood and OSB don’t have the same benefits of wood grain that solid woods have. The direction of the wood grain in solid woods is a major help to holding in fasteners, especially in more dense lumber. Plywood is glued together thin sheets of wood, and OSB is compresses strands of wood. Engineered woods are however incredibly popular in construction as they meet code requirements and are significantly cheaper. While plywood tends to perform slightly better when it comes to pull out strength, OSB is comparable.

When it comes to getting the best possible pull out strength in engineered woods, the thickness of the wood is beneficial, as a greater depth for the fastener can slightly increase the pull out strength. However, what effects pull out the most in engineered woods are the fasteners themselves. Using a larger diameter fastener, and if available, a fastener with deep threads, will increase the pull out strength in engineered woods.

Why Does This Matter?

Some might be wondering why they should care about pull out strength at all. Under what circumstances might a fastener be put under the kind of stress that would cause it to pull out? When it comes to metal roofing, the answer can be summed up in one word. Uplift. The ability for wind to get under the panels and lift them is something that needs to be considered in the planning stage. An architect or engineer will often be a part of calculating potential uplift based on the design or basic wind speed (determined by geographic location), the roof pitch, the size of the panels, and other factors. This will then go into determining the best way to distribute the uplift between fasteners to ensure that no single point is overwhelmed causing the fasteners to fail.